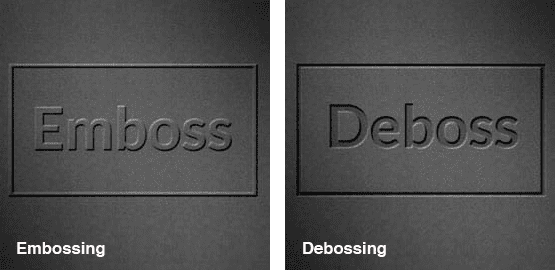

Embossing and Debossing

Embossing is a printing technique that creates a raised shape or image on selected areas of paper, resulting in a three-dimensional effect that provides a tactile and visual contrast against the flatness of the rest of the sheet.

This method is commonly used when a high-end, custom look is desired, such as for wedding stationery, letterheads, folders, certificates, packaging, and more. It can also serve as a security measure against counterfeiting.

How is embossing applied

The process of embossing involves placing the paper between two metal dies, where the die underneath the paper has the raised pattern and the die on top of the paper (the counter die) has a recessed version of the same pattern. When the two dies are pressed together using heat and pressure, the paper is forced into the recessed die, causing the paper fibers to be squeezed and creating the permanently embossed area.

Types of embossing

Blind Embossing

Blind embossing refers to the process of creating a raised, textured design on paper without the use of ink or foil. It is called “blind” because there is no color or foil applied to the embossed area, making it visible only through the contrast of light and shadow. Blind embossing can be used to create elegant and understated designs, and is often combined with other printing techniques, such as letterpress or foil stamping, to add an extra layer of texture and detail to a printed piece.

Registered Embossing

Registered embossing is a technique that ensures the embossed area is in precise registration with printed elements on the same sheet. This technique is commonly used for products such as stationery, business cards, and invitations where it is important for the embossed area to align perfectly with logos or text.

Combination Embossing

The combination of embossing with other print finishes like foil or spot UV varnish can create a very striking effect, particularly when used on logos or other important elements. Using a second embossed area can also provide even more contrast and depth to the design. This technique is commonly used in high-end packaging, business cards, and invitations to create a truly luxurious and eye-catching look.

Debossing

Pillow boxes can also be enhanced with debossing, which is similar to embossing in terms of process but with reversed metal dies that create a recessed or indented area on the paper. This technique can be applied to the pillow box surface to create a subtle yet striking effect, either with a plain and unprinted debossed area or by filling it with ink or foil.

Things to consider before you start

Artwork

For best results, it’s recommended to use vector files as they can be easily scaled up or down without losing quality in the embossing process. To make sure the embossing stands out, it’s best to keep the design simple and avoid shading. Using a single color can also help prevent the embossing from being lost in the print, especially if combination embossing is being used.

Choosing the embossed area

It’s important to remember that less is often more when it comes to embossing. The wow factor of the embossing is often maximized when it is used sparingly, but it really depends on the specific item you are working on. For example, you may wish to have an all-over embossed or debossed pattern on a pillow box, with a registered or combination embossed area to contrast the background pattern. Ultimately, it comes down to personal preference and what will work best for your particular project.

Choosing the pattern and Paper weight

When selecting the depth of your embossing, it’s important to consider the size and intricacy of the area to be embossed. Small areas are not suitable for deep embossing as the paper may tear. If multi-level embossing is used, it’s best to use the deeper levels in the less intricate areas to avoid causing distress to the paper.

It’s also important to consider the weight of the paper, as it needs to be thick enough to accommodate the depth of the embossing without becoming weakened. A heavy paper weight is recommended for deep embossing, as it will allow for a more detailed and pronounced image. This is especially important for pillow boxes, as the weight of the paper will affect the structural integrity of the box.

Consider the reverse

When embossing or debossing, the paper will be pushed through to the other side of the sheet, creating a raised or recessed area on the opposite side. It’s important to take this into consideration when designing and printing on both sides of the paper.

If you have any further questions about embossing or debossing then call us on 023 8087 8037 or email us.